Conveyor idlers come in various types, each serving a specific purpose.

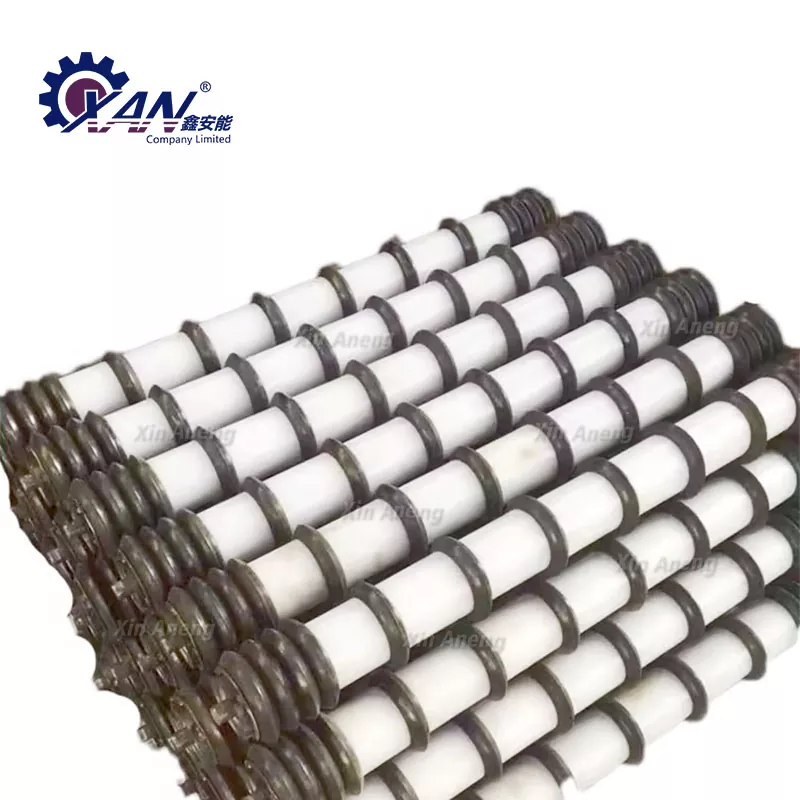

1. Impact idlers are designed to absorb the impact of materials falling onto the conveyor belt, reducing damage and extending belt life.

2.Return idlers support the return run of the belt, ensuring proper tension and alignment.

3.Training idlers help to keep the belt aligned, preventing it from wandering off course.

Each type plays a vital role in the overall performance of the conveyor system.

Conveyor idlers has a few key functions in a belt conveyor system. They provide support to the conveyor belt, and help to maintain correct tension in the belt, which is essential for optimal performance. besides, idlers assist the belt along the conveyor path, reducing the risk of misalignment or damage.

The high-quality conveyor idlers will significant benefit for the belt conveyor system and operations. The reliable idlers help prevent belt slippage and other issues that can pose risks to workers.

When selecting conveyor idlers for your system, several factors should be considered.

1. Load capacity is important, as idlers must be able to support the weight of the materials being conveyed.

2.Material is another important consideration, as idlers should be made from durable materials that can withstand the conditions of your operation.

3.Size and spacing of idlers should also be correctly chosen to guarantee proper belt support and alignment.

TradeManager

Skype

VKontakte