In the process of long-term use of the conveyor belt, it is inevitable to encounter longitudinal tear of the conveyor belt, cracks of the conveyor belt, and damage to the belt surface of the conveyor belt, which we call the conventional damage of the conveyor belt. It not only causes trouble to itself, but more importantly, it causes unnecessary economic losses to the enterprise.

How can these situations be prevented? Let's briefly analyze the reasons for this.

(1) Vibration and impact cause fasteners to loosen and fall off, resulting in the fall of the coal pipe lining plate and material guide plate.

(2) The material is mixed with foreign substances, which are hard and angular, and the coal pipe is blocked and squeezed to death.

(3) The roller is defective, and the roller frame causes scratches.

(4) The conveyor belt is hung by the frame after serious deviation.

(5) The cleaner is involved in the drum (return cleaner), the bolt is loose, and there is a precursor of bouncing.

(1) Due to the limitation of space size, the number of bending of the conveyor belt is large.

(2) The vulcanization of the joint has been carried out more than twice due to various reasons.

(1) The diameter of the reversing pulley is small, and the bending stress of the conveyor belt is large.

(2) The quality of the vulcanized joint of the conveyor belt is poor, especially if the vulcanization is more than twice, the strength of the joint decreases significantly, or the canvas layer is cut during gluing, or the polishing leaks, and the strength is reduced here.

(3) For the reversible conveyor, because the upper and lower lap can only be in one direction, it is easy to be scratched by the sharp corners of the cleaner, discharger and other equipment on the belt.

(4) The working cycle of the conveyor is short, the start is frequent, and the instantaneous tension force is large.

(1) The gap between the lining plate of the guide groove and the tape is not suitable, resulting in abnormal wear, or foreign objects are embedded in the gap, resulting in abnormal wear or scratches.

(2) The material flow rate at the guide trough is inconsistent with the speed of the conveyor belt, and the drop is large, which accelerates the wear of the rubber surface.

(3) The roller is damaged, resulting in abnormal wear or scratches of the tape.

(4) Illegal operations, welding slag scalding during maintenance, and cleaner scratches.

(5) Slipping of the tape will also cause abnormal wear of the tape.

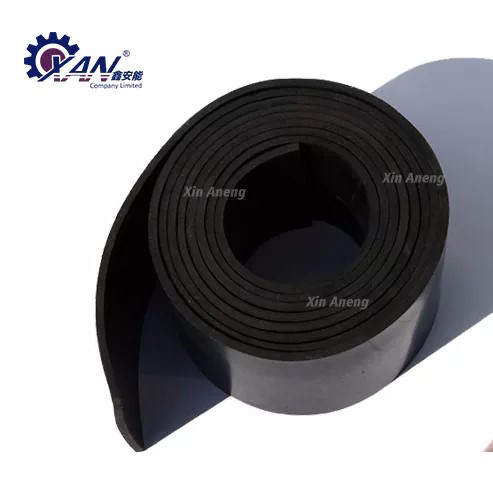

In the process of conveyor belt use, the most common problems are: foreign body scratches, local foreign body damage, wear, perforation, etc.

Usually the conveyor belt is partially damaged due to foreign matter, and according to the traditional method, it is completely disassembled, repaired, heated and vulcanized, or scrapped and replaced.

It can be repaired using polymer rubber materials, which have super adhesion, excellent wear resistance and excellent tensile properties. The use of polymer rubber repair materials, disassembly-free, heat-free vulcanization on-site repair of rubber conveyor belt scratches, low repair cost, short time, to avoid scrap replacement and long-term shutdown caused by heavy losses, and the repaired conveyor belt can fully reach the service life of the new transmission.

The thickness of the repair coating is controllable, the forming is fast, and the application time is short. The cured coating has very high cohesive strength, tensile strength, peel strength and good hardness, toughness and elongation. It can greatly simplify the repair construction process, with good self-leveling and bright appearance. It can not only quickly repair damaged rubber conveyor belts and rubber products, but also pre-coat a protective layer on the surface of the products to prolong the service life.

TradeManager

Skype

VKontakte