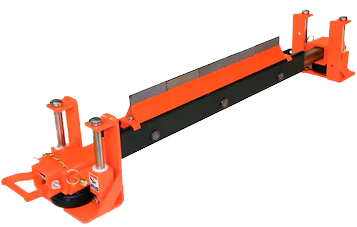

Conveyor cleaner is a device used to clean conveyors, in the process of conveying materials in the belt conveyor, if the residual adherent materials enter the roller or roller bearing seat, the bearing wear will be accelerated, and the material on the surface of the roller or roller will tear and pull the conveyor belt adhesive, accelerating the wear and damage of the conveyor belt.

In the process of conveying materials on the belt conveyor, if the residual adherent materials enter the roller or roller bearing seat, the bearing wear will be accelerated, and the materials on the surface of the roller or roller will tear and pull the conveyor belt adhesive, accelerating the wear and damage of the conveyor belt. If the material is attached to the surface of the reversing roller or vertically tensioning the drum at the tail of the belt conveyor, it will cause the conveyor belt to deviate, increase the wear of the conveyor belt, and even tear the rubber layer of the pulley, which will cause serious consequences.

If the cleaning device has a good effect, the service life of the roller, conveyor belt, roller, etc. can be extended; Therefore, the cleaning capacity of the cleaner plays a pivotal role in improving the operation efficiency and reliability of the belt conveyor, reducing the equipment failure rate and reducing the maintenance cost.

Technical requirements for conveyor belt cleaning systems

1. Extremely high cleaning performance.

2. Protect the conveyor belt.

3. Self-cleaning effect

4. Fire prevention.

5. No hidden danger of accidents.

6. Small amount of maintenance.

7. Cost savings.

8. Long service life.

9. Low cost wear parts.

10. Easy to install.

Cleaner classification

Conveyor Cleaners, Rotary Cleaners, Polyurethane Cleaners, Alloy Rubber Cleaners, Spring Cleaners, Belt Conveyor Cleaners, Brush Cleaners, Electric Vacuum Cleaners, Enclosed Cleaners, Scraper Cleaners, Electric Roller Brush Cleaners, etc.