The function of the idler roller is to support the conveyor belt and the weight of the material. The roller must be flexible and reliable. Reducing the friction between the belt and the idler plays a key role in the life of the belt, which accounts for more than 25% of the total conveyor cost. Although the idler is a small component in a belt conveyor and the structure is not complicated, it is not an easy task to manufacture a high-quality idler.The criteria for judging the quality of the roller are as follows: radial runout of the roller; roller flexibility; Axial channeling momentum.

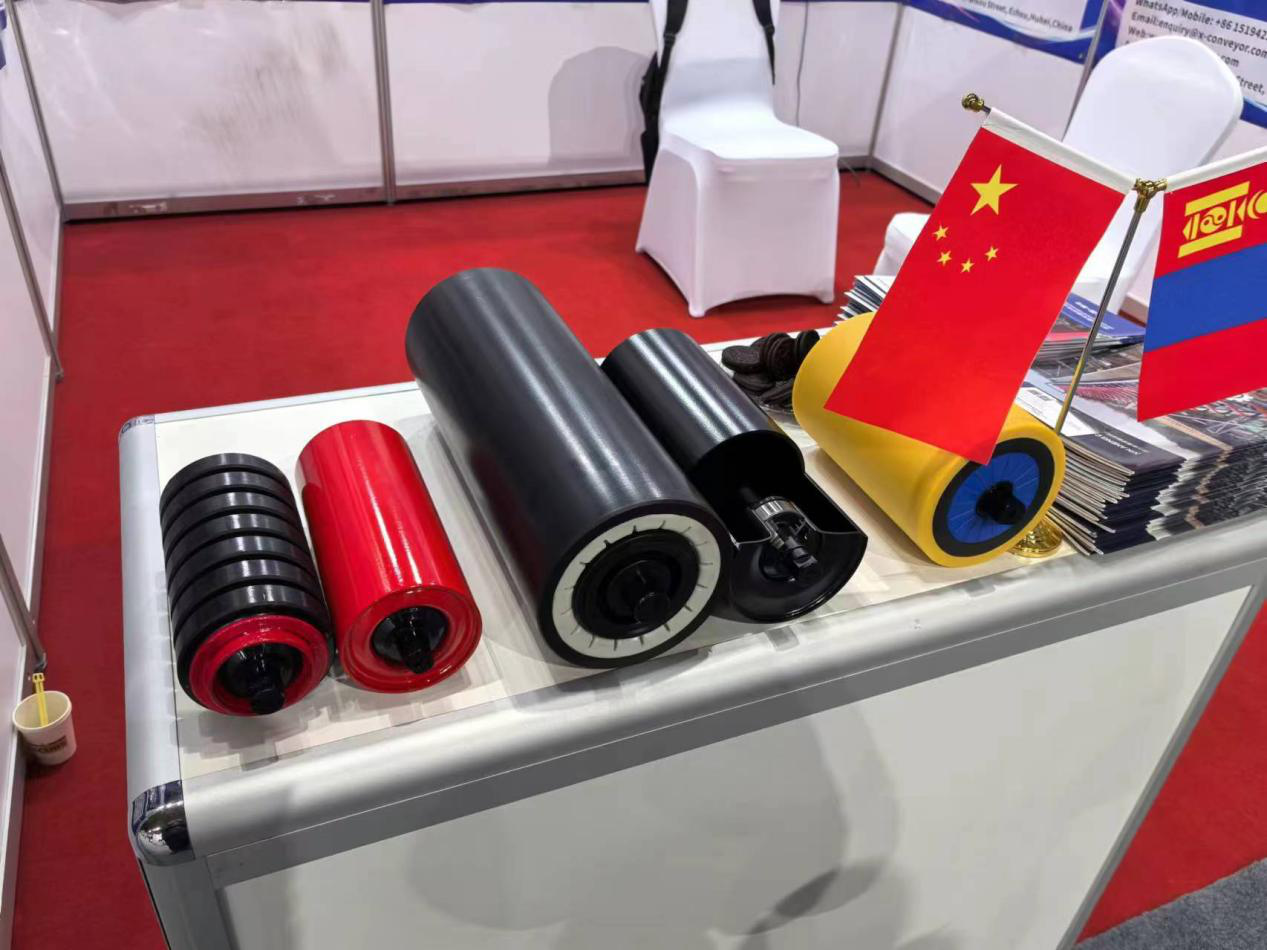

Impact idler, the impact idler is used to slow down the impact of the blanking on the conveyor belt at the receiving place of the belt conveyor, mainly for the corrosive environment of coal washing plants, coking plants, chemical plants and other corrosive environments, it has more than 10 times the toughness of ordinary metals, five times the life of traditional column shoes, corrosion resistance and flame retardant, antistatic, light weight and other characteristics, widely used in mining. The special polymer material for the roller body has similar mechanical properties to bronze, has good wear resistance, and has good self-lubricating performance, which does not hurt the belt. The buffer roller has superior anti-corrosion performance. The roller body and seals are made of polymer materials, which are corrosion-resistant. When used in corrosive occasions, the service life can reach more than 5 times that of ordinary rollers.

The buffer roller is light in weight and has little rotational inertia. The special polymer material for the roller is light in weight, the specific gravity is one-seventh of that of steel, and the roller made of this material is about one-half of the weight of the ordinary roller, the rotational inertia is small, and the friction between the roller and the belt is small.

The buffer roller is installed below the receiving section of the conveyor to reduce the impact of the material on the conveyor belt during blanking, so as to prolong the service life of the conveyor belt. The spacing of the buffer rollers is generally 100-600 mm.

In terms of installation, the buffer roller is to improve the density of installation; The second is to check frequently and replace the damaged roller in time. For conveyor belts with large blanking drops, it is recommended to install a buffer air lock, and replace the buffer roller with a buffer bed. In terms of purchase, the following precautions are put forward according to the characteristics of the buffer roller: radial runout of the roller, flexibility of the roller, axial channeling momentum, dustproof performance of the roller, waterproof performance, axial bearing performance of the roller, impact resistance of the roller, etc.

When the friction between the belt conveyor roller and the belt makes the temperature exceed the limit, the detection device installed close to the roller sends an overtemperature signal, and after the receiver receives the signal, after 3s delay, it makes the execution of part of the action, cut off the power supply of the motor, and the conveyor automatically stops, which plays a role in temperature protection.

If the conveyor fails, such as the motor burns out, the mechanical transmission part is damaged, the belt or chain is broken, the belt is slipped, etc., and the magnetic switch in the accident sensor SG installed on the conveyor is motive can not be closed or cannot be closed at the normal speed, then the control system will be according to the anti-time limit characteristics after a certain delay, and the speed protection circuit will play a role, so that part of the action can be performed, and the power supply of the motor will be cut off to avoid the expansion of the accident.

Coal bunker is provided with high and low two coal level electrodes, when the coal bunker can not put coal due to no empty car, the coal level will gradually rise, when the coal level rises to the high electrode, the coal level protection action, starting from the first belt conveyor, each conveyor stops in turn because of the tail pile of coal.

TradeManager

Skype

VKontakte